Return to Innovative Gear Testing

In February 2020, the Minister of Fisheries and Oceans and the Canadian Coast Guard and the Minister of Transport, announced that Canada would be implementing additional protection measures to prevent future entanglements of marine mammals, particularly, North Atlantic Right Whales. This announcement included the potential to introduce gear modifications that were deemed ‘whale-safe’ to fixed gear fisheries throughout Atlantic Canada.

The Department of Fisheries and Oceans Canada [DFO] established the Whale Safe Gear Fund (WSGF) in 2021 to encourage rope manufacturers, ocean technological companies, and others to further advance research and development into innovative fishing gear and to have such products tested by harvesters themselves. In response to this announcement, Coldwater Lobster Association (CLA) agreed to ‘test’ several innovative gear types during regular fishing operations, which included different types of ‘weak’ rope and weak links inserted into their vertical lines (endlines).

No Fishing Area is the Same…

Every fishery area in Atlantic Canada is different and every Lobster Fishing Area (LFA) and Crab Fishing Area (CFA) presents distinct challenges and obstacles, from the depths of water they fish, different bottom types, tide strength (LFA 34 has some of the strongest currents in Atlantic Canada), sea state can vary considerably due to the timing/seasonality of the fishing activity, and lastly, the way we fish (i.e. trawl versus single or doubles).

Without considering these very important factors, innovative gear types cannot truly be evaluated for their effectiveness and suitability for a particular area.

Enginuity Inc. – Load Reading System

CLA solicited the expertise of Enginuity Inc., an engineering firm based out of Halifax, Nova Scotia, as a third-party project partner to:

- Design and fabricate a custom load reading system, capable of handling the winter sea state conditions in LFA 34 as well as a custom fabricated block (see photo below);

- Retrieve, compile, and analyze load readings; and

- Compose technical assessment report based on the findings during the Innovative Gear trials. Key components of the report will include vertical line load readings, innovative gear performance and condition, and safety issues, if any.

Tensile Strength Testing

Third-party tensile strength testing will be conducted on the innovative gear types being trialed. This testing will confirm/refute the manufacturer’s claimed specifications an allow for an evaluation of the rope’s breaking strength before and after use (degradation).

Methodology

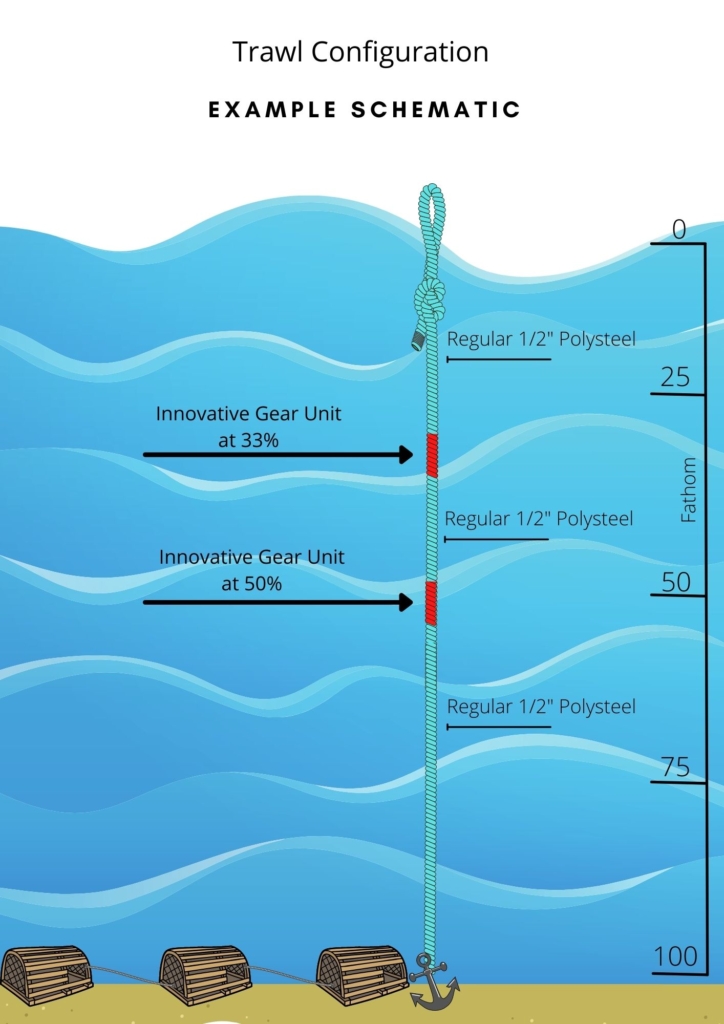

All gear types trialed will follow the same configuration: a weak link inserted in the endline at the top 33% and at the 50% mark of a endline.

Should an innovative gear fail at the 50% mark at least three times, that unit will be removed. Only the unit at the top 33% will remain.

Should an innovative gear fail at the top 33% mark at least three times, it will be removed from testing indefinitely.

Trial Results – Pending

The results of the gear trials will be presented in the final technical assessment report in 2023.

Media